Image: science photo, Shutterstock.

June 27th, 2019 - by Nathan Collins

Enzymes make life possible. Without them, the basic biochemical reactions that keep every plant, animal and bacteria on earth alive would otherwise take months, years even millenia to run. But a deep understanding of how they work has eluded scientists, because standard methods failed to make sense of enzymes’ size and complexity.

Now, Stanford researchers say they’ve found a new way to tackle that complexity and, perhaps, reveal something more fundamental about the way enzymes work.

With help from a Stanford Bio-X seed grant, they’ve used a relatively new tool known as microfluidics, which automates many of the steps researchers once had to do by hand, to dramatically speed up the process.

In the long run, those techniques could transform the way researchers study enzymes and perhaps someday other fields as well, said Polly Fordyce, an assistant professor of genetics and of bioengineering, who is leading the project with Daniel Herschlag, a professor of biochemistry.

“With enough understanding of how enzymes work, we should be able to build enzymes to do the things that we want, like developing therapies to cure disease or creating new enzymes for green chemistry or environmental remediation,” said Fordyce, who is also a faculty fellow of Stanford ChEM-H. “Linus Pauling said in 1945 that a full understanding of enzyme function would enable efficient enzyme design, but this hasn’t been possible yet.”

Studying enzyme function at this scale has required a willingness to learn the language of each other’s disciplines – enzymology for Herschlag and microfluidics for Fordyce – the scientists said.

Our ignorance of how enzymes do their jobs is the result of a mismatch between enzymes’ size and complexity and the methods researchers deploy to study them. A typical enzyme comprises hundreds of individual units called amino acids that somehow work together to do everything from speeding digestion to aiding the formation of memories.

Yet to study an enzyme, researchers usually swap out one of its amino acids, see how the swap affects a biochemical reaction, then repeat. A typical research study, Herschlag said, might look at a dozen such variations – meaning not only that progress is slow, but also that scientists can’t see how the individual units combine to drive the function of the whole enzyme.

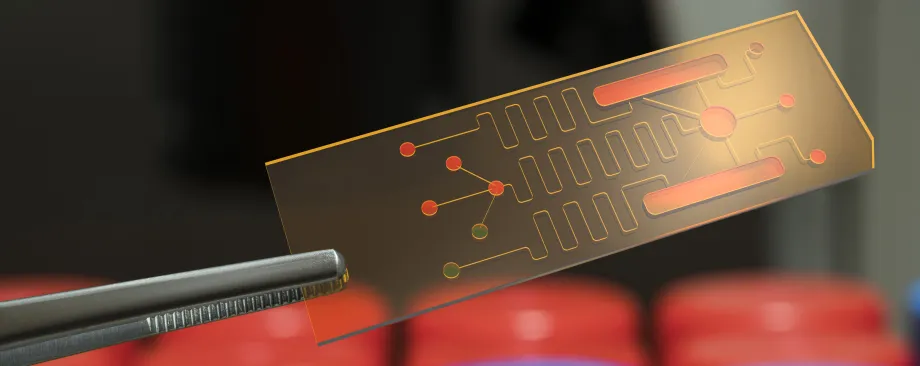

One way to overcome those limitations is microfluidics, a set of techniques that focuses on running many similar experiments in parallel while using less raw material than conventional lab methods. The key is that the most labor-intensive steps are run on precision-built chips perhaps a few inches wide, each one containing thousands of tiny chambers where the chemistry happens. With the flip of a switch, a researcher can simultaneously step each well through a series of reactions – meaning that the number of tasks a research can run at once is only limited by how many chambers they can fit on a chip.

In the case of enzymes, the Fordyce and Herschlag labs print chips with 1500 chambers, meaning they can tweak an enzyme 1500 different ways at once and rapidly develop a much fuller picture than was previously possible of how an enzyme works.

Right now, Fordyce and Herschlag’s labs are working together to more fully characterize just one enzyme. From there, their microfluidic approach could be used on hundreds of enzymes. By studying a wide variety of these molecules and potential chemical reactions, they hope to discover generalizable principles that govern how enzymes are put together and reveal how to design enzymes with new capabilities.

Herschlag is a member of Bio-X, ChEM-H and the Stanford Cancer Institute. The project was also funded in part by a grant from the National Institute of Standards and Technology’s Joint Initiative for Metrology in Biology.